Parallel Transistors - Night 3

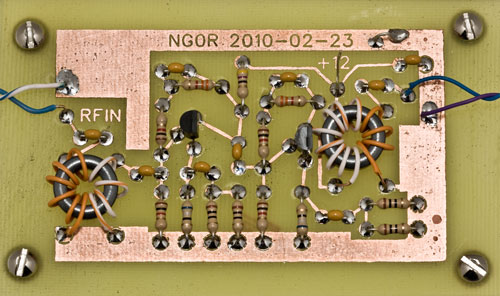

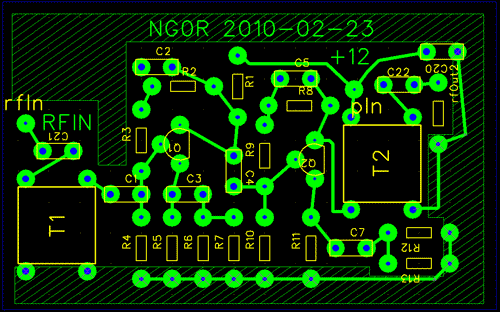

Tonight I converted the schematic to a layout for a printed circuit board.

I had several realizations tonight as I was laying this out.

The new circuit board is remarkably simple compared to what I was playing with two

hours ago. Quite a few tweaks in my process as I spend some time bonding with FreePCB.

I think that this will probably one of three boards that I will try to etch on Saturday.

I had several realizations tonight as I was laying this out.

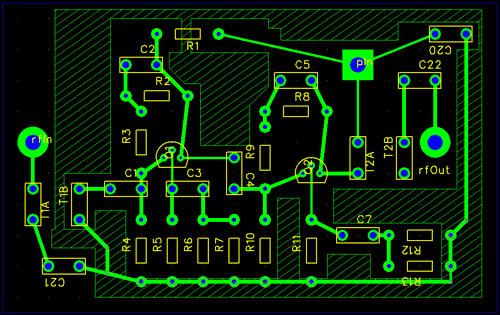

I removed the parallel base resistors and replaced it with a single resistor.

(I was battling a nightmare trying to route it on a single sided board when I realized

that it was overkill and could be simplified. Wow... what a difference.)

I converted my 120 mil parts to 70 mil parts.

(Now that my #67 drill bits have arrived I can work with much smaller pads even on

home brew boards.)

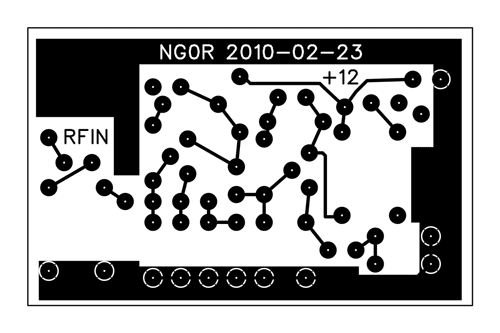

The backplane of the board is now solid copper.

(I have been wanting to test this and it was extremely simple.)

I figured out how to change the pilot hole size.

(Used to center the drill bit)

I figured out how to change the size of the "copper-to-copper fill clearance"

(15 mil looks pretty nice... I need to test it.)

I figured out how to change the "hole-edge to copper-fill clearance"

(15 mil looks pretty nice... I need to test it.)

I can now route traces under/through other parts as needed as I start using smaller

traces.

I expect this approach should etch much quicker as I am not removing nearly as much

copper.

The new circuit board is remarkably simple compared to what I was playing with two

hours ago. Quite a few tweaks in my process as I spend some time bonding with FreePCB.

I think that this will probably one of three boards that I will try to etch on Saturday.