PCB Design

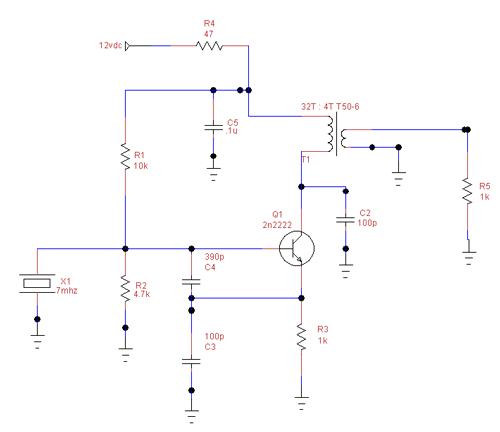

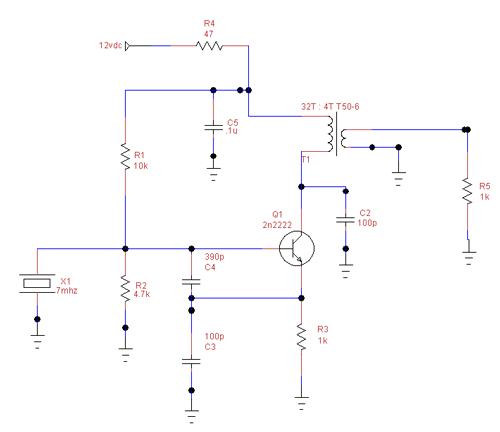

I spent some time

last night working on getting a schematic laid out in TinyCad.

I had a couple of issues that took me a little to resolve since it was my first time

laying something with it. Getting my ground to work as an actual ground and

then I had a couple of components where the wires would not properly connect even

though the junctions were good. I resolved all of the ground issues... and most

of the junction issues. I then exported it to a netlist and

partslist.

last night working on getting a schematic laid out in TinyCad.

I had a couple of issues that took me a little to resolve since it was my first time

laying something with it. Getting my ground to work as an actual ground and

then I had a couple of components where the wires would not properly connect even

though the junctions were good. I resolved all of the ground issues... and most

of the junction issues. I then exported it to a netlist and

partslist.

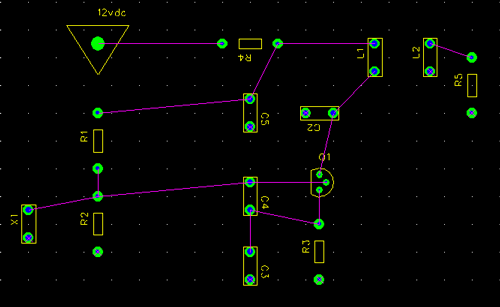

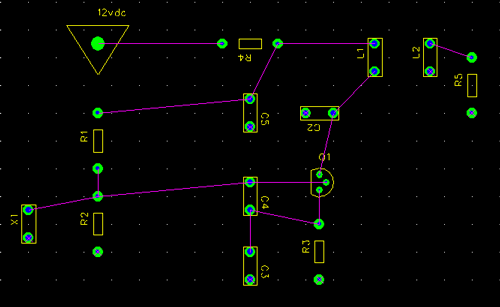

Next I moved on

to FreePCB. I was able to import

my netlist and

partslist right way. I then updated the package/footprint info and then started doing

the parts placement. The couple of places where I had junction issues came back as

an issue. I ended up just deleting the network for that connection and manually connected

the parts. Once a person figures that out it is a quick fix. I then decided that I

wanted a two sided board so that it would work with the autorouter software. I then

created a dsn file. (I used generic pads for the toroid based transformer.)

to FreePCB. I was able to import

my netlist and

partslist right way. I then updated the package/footprint info and then started doing

the parts placement. The couple of places where I had junction issues came back as

an issue. I ended up just deleting the network for that connection and manually connected

the parts. Once a person figures that out it is a quick fix. I then decided that I

wanted a two sided board so that it would work with the autorouter software. I then

created a dsn file. (I used generic pads for the toroid based transformer.)

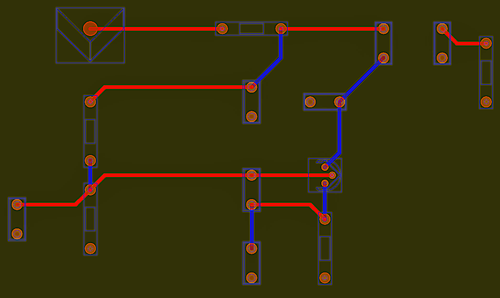

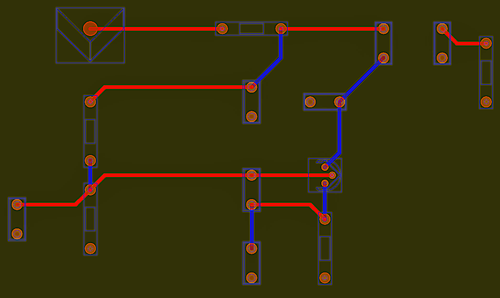

Next I opened the

dsn file with the Autorouter software. It laid out the connections in a couple

of seconds. The problem is that four of the traces were on the bottom of the board

which is an issue when I want to work on a one sided solder mask. I then exported

my updated dsn file and exported my spectra file.

dsn file with the Autorouter software. It laid out the connections in a couple

of seconds. The problem is that four of the traces were on the bottom of the board

which is an issue when I want to work on a one sided solder mask. I then exported

my updated dsn file and exported my spectra file.

Next I went back

to FreePCB and opened my updated

DSN and spectra files. I discovered that I can click on the traces and change them

back to top layer. That is a very cool hack to make my simple board a single sided

board again... traces on top... ground on the bottom. I then exported the CAM files

so that I would have some Gerber files to work with.

to FreePCB and opened my updated

DSN and spectra files. I discovered that I can click on the traces and change them

back to top layer. That is a very cool hack to make my simple board a single sided

board again... traces on top... ground on the bottom. I then exported the CAM files

so that I would have some Gerber files to work with.

Next I opened up Viewmate and

opened up my Gerber

files. I was able to select my layer(s) and save them as BMPs or send them to

the laser printer or cutepdf. If I owned the app for the $49 I would have several other

options as well.

opened up my Gerber

files. I was able to select my layer(s) and save them as BMPs or send them to

the laser printer or cutepdf. If I owned the app for the $49 I would have several other

options as well.

I probably spent

4 hours end to end for my first time through the process. I could have easily made

a working "print & peel" or if I had a flatbed inkjet printed directly on a board.

Granted that my schematic was pretty simple but the process would have worked. I

did quick measurements and the capacitors that I ordered would have fit the pad

foot print on my board. The crystal pads should be adjusted to be a bit bigger

and the toroid pads probably should be spaced out a bit further as well.)

4 hours end to end for my first time through the process. I could have easily made

a working "print & peel" or if I had a flatbed inkjet printed directly on a board.

Granted that my schematic was pretty simple but the process would have worked. I

did quick measurements and the capacitors that I ordered would have fit the pad

foot print on my board. The crystal pads should be adjusted to be a bit bigger

and the toroid pads probably should be spaced out a bit further as well.)

So overall I would

rate the experience as a B or B+ especially given that I am not an EE nor do

I have any experience with this kind of software or tools. (All of the software that I

used last night was open source or free.)

rate the experience as a B or B+ especially given that I am not an EE nor do

I have any experience with this kind of software or tools. (All of the software that I

used last night was open source or free.)