I am planning on making some printed circuit boards this weekend. Since I need to get out the chemicals & related supplies I might as well make several boards. So in addition to the board for the parallel NPN transistors I thought that I would make up some 2N7000 FET experiments as well.

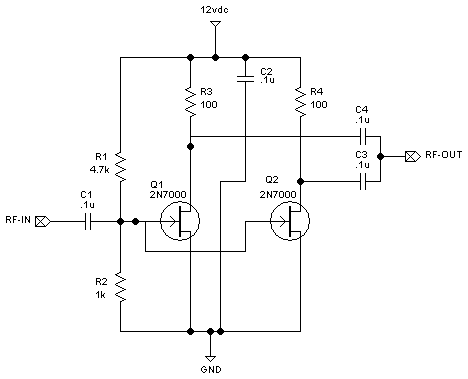

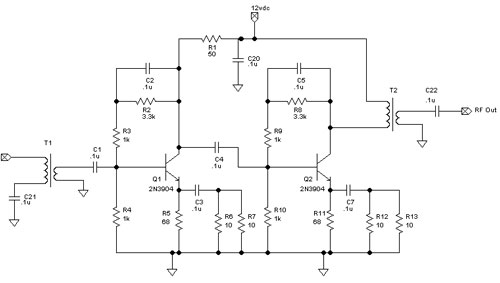

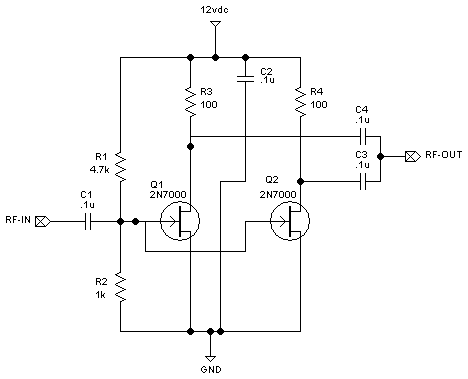

The circuit below is a dual FET design. The FETs are in parallel running in class

A. The Gate is biased for approximately 2 volts of DC drive with virtually no current

with assuming a bench power supply of 12-13.5 volts.

(R3 and R4 are high values

for current limiting aka to avoid self destruction.) The 2N7000 is rated for 200mA

of safe current. (200mA would suggest a drain resistor of approximately 68ohms.) I

don't really want to waste that much current but I want to see what this will draw.

I would prefer that it consume current less than my NPN experiments which is about

25mA per device with 15 to 17dB of gain per device. (I assume that I will be changing

the drain resistors once I know more about this FET.)

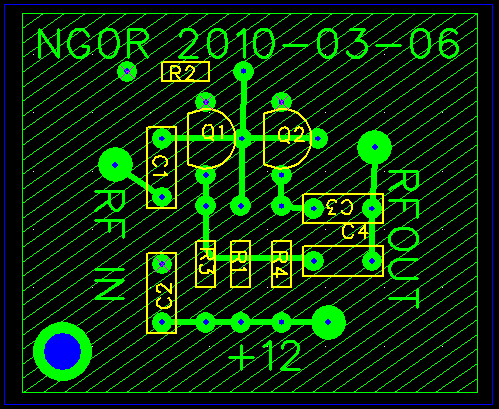

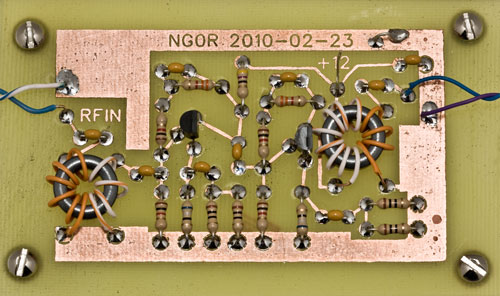

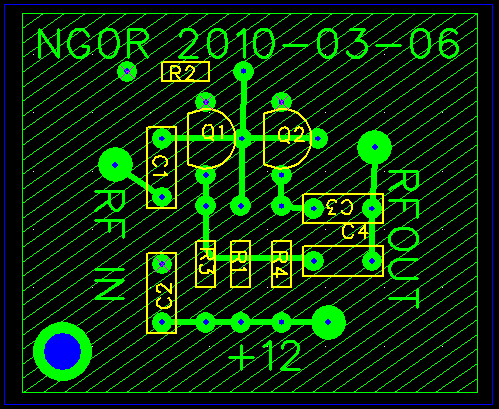

The image below shows what it looks like after spending a little bit of time bonding

with FreePCB. (The blue circle in the bottom left is a small hole to hold/retrieve

the board in the etchant bath.)

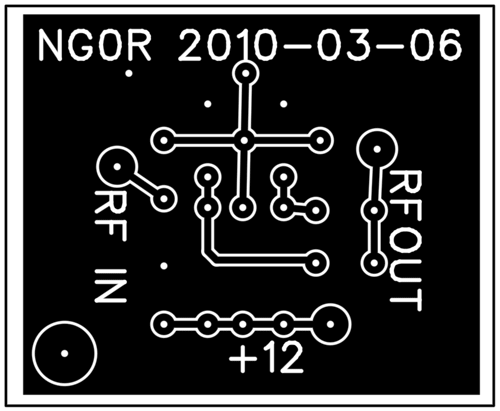

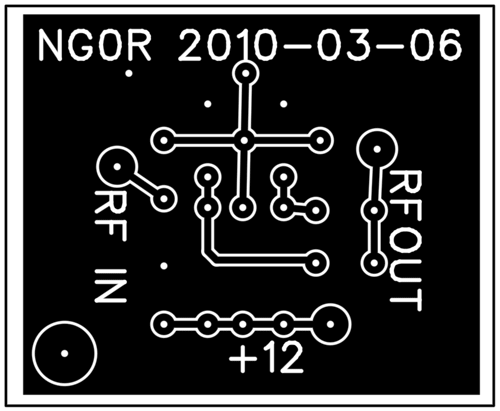

The image below shows what the copper will look like (in black.) The white

areas will be removed by the etchant. The board looks big on the web but it is actually

only about 1.5 x 1.5 inches total. (If I removed the text and extra space it could

easily be condensed down to less than 1 x 1 inch.)

I don't know that I would would ever really use a design like this in the real world

but I want to get a feel for how it performs. I have NOT used FETs in any of my designs

or experiments yet so this is a good starting point.

Bipolar Junction Transistors are current devices. Field Effect Transistors are voltage

devices. It is interesting working with each of them as they have different design

considerations.

Some additional notes (before people start sending me emails):

The input impedance of this circuit is pretty high. It is not clear what high impedance

is other than to say it could be way north of 1K. In this initial test I am not making

any attempt to match the input. (That is why it is test.)

If I was going to try to match the input to something like my signal generator I would

probably use a 1:4 or 1:5 turns ratio to take the 50 ohm source and transform it to

between 800 and 1250 ohms.

The output of this should be approximately what the drain resistor value is. In this

case it should see two 100 ohm resistors in parallel or 50 ohms. (I might be changing

these resistors once I do some testing so it is a bit early to be too worried about

matching the circuit. I would also need to now what the next circuit stage is that

we need to integrate with.) It would be easy enough to wind a transformer on a

T50-43 core to step-up/step-down as needed.

FETs are voltage sensitive. Looking at the data sheet it appears that 60 volts

is the max that the 2N7000 can handle. In a design for a "real" circuit it might be

worth considering adding a zener diode to the drain to shunt off the excess voltage

should it appear. (An example is running this circuit without having a load attached...

it could spike the voltage on the drain to a fatal level. I have a limited number

of 33 volt zeners on hand but that would potential for a design like this. For this

test I am not going to worry about it. If I decide to use FETs in a "real" project

I would probably include them.)

73 de NG0R